In the global race towards net zero, building professionals are under increasing pressure to choose products that meet both performance and sustainability goals. When it comes to solar thermal collectors, most available solutions still rely on outdated manufacturing practices and bulky, non-recyclable designs. And this is where the SolarisKit HelioFlow comes in– a modern solar water heater solution built around the principles of circular design.

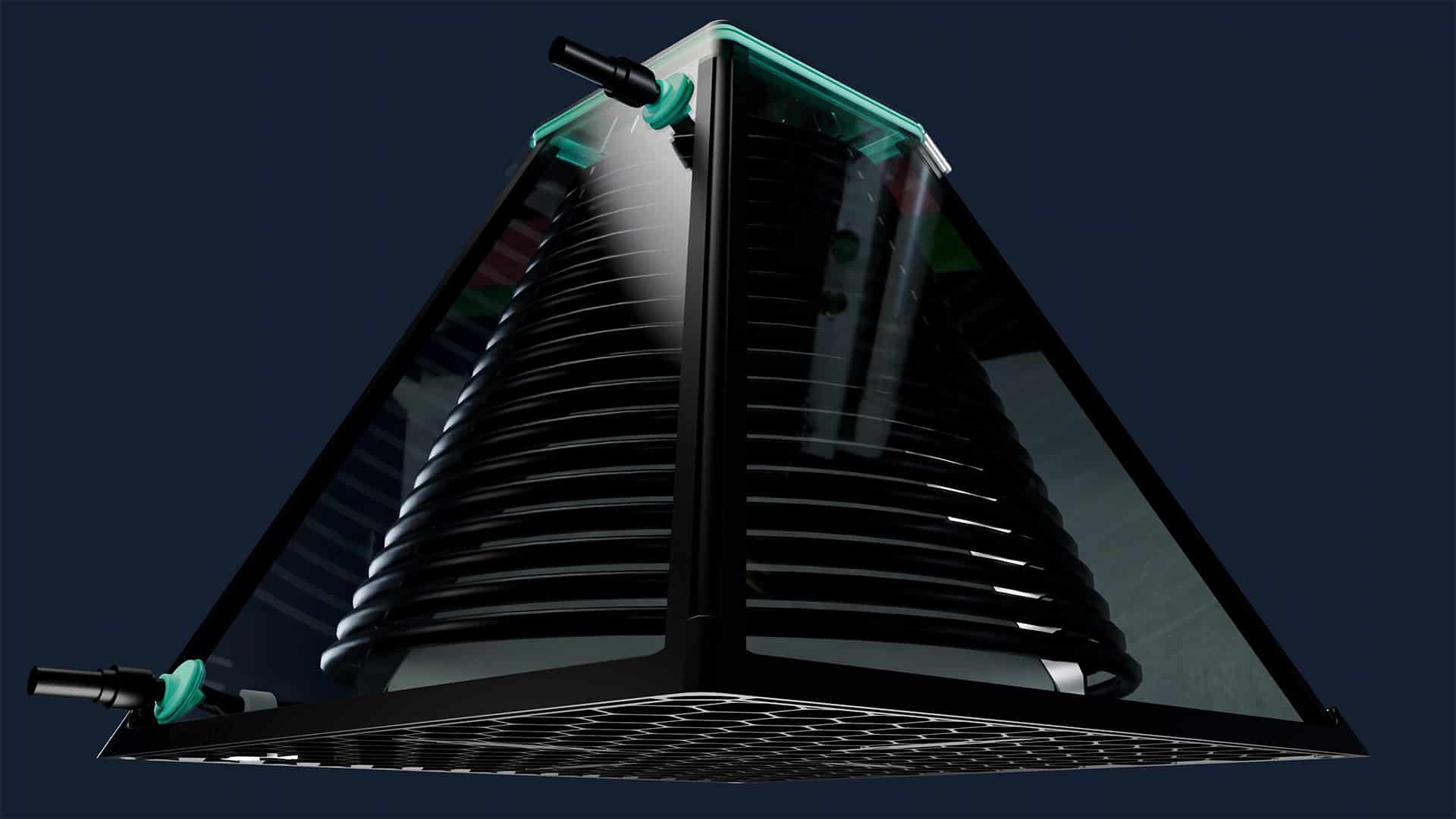

Unlike traditional flat-plate and evacuated tube solar thermal collectors, the HelioFlow solar collector redefines how sustainability is engineered. Designed to minimise embodied carbon, simplify shipping, and maximise end-of-life recoverability, HelioFlow is the smart choice for forward-thinking MEP engineers and green building consultants.

Rethinking Solar thermal with Circular Design Principles

The construction industry is increasingly adopting circular economy strategies to reduce environmental impact. However, most solar water heaters still follow a linear model of take, make, and dispose. Flat-plate and evacuated tube systems are difficult to disassemble, challenging to repair, and frequently end up in landfill.

In contrast, the HelioFlow solar collector was designed from the ground up with circularity in mind. From the choice of materials to the modular assembly, each element of the product can be accessed, repaired, replaced, or recycled.

A Flat-Packed Solar Collector for Global Efficiency

One of the most unique and impactful aspects of the HelioFlow is its flat-packed design. This innovation allows multiple units to be shipped efficiently, significantly lowering emissions associated with transport. While traditional solar thermal collectors require bulky packaging and are prone to damage during shipping, HelioFlow units are compact, lightweight, and easily assembled on-site.

SolarisKit HelioFlow is the world’s first flat-packed solar thermal collector

This not only reduces embodied carbon from logistics but also makes it easier to deploy solar water heating systems in remote or off-grid locations. In developing markets or urban high-rises, this flexibility can be game-changing.

Moreover, the flat-pack format simplifies warehousing and local distribution. Installers can store more units in less space, saving time, money, and emissions across the entire supply chain. A total of 52 HelioFlow solar collectors can be stacked on a single pallet. Enough to provide 2,000 litres of hot water per day in the UAE.

52 x SolarisKit HelioFlow solar collectors can be stacked on a pallet. Enough to provide 2,000 litres of hot water per day.

Low Embodied Carbon Through Smart Manufacturing

In the drive to reduce whole-life carbon, embodied emissions during production must be minimised. Traditional flat-plate and evacuated tube collectors use energy-intensive manufacturing processes involving glass, copper, and aluminium.

HelioFlow’s design avoids these high-carbon materials. Instead, it utilises recyclable polymer components that require less energy to produce. These materials are also resistant to corrosion, scale, and impact damage – extending the product lifespan and further reducing environmental impact.

By replacing metal-heavy construction with high-performance polymers, SolarisKit has engineered a solution with a significantly lower embodied carbon footprint without compromising thermal performance.

Easy Repair and Maintenance for Extended Lifespan

In a circular economy, keeping products in use for as long as possible is critical. Most flat-plate and evacuated tube collectors are difficult to repair. Components are welded or sealed, making access nearly impossible without special tools or factory service.

HelioFlow solves this problem by enabling access to every component. The collector can be disassembled with basic tools, making it easy to replace worn or damaged parts. This reduces waste, lowers lifetime costs, and gives MEP engineers a more durable and dependable solution.

Moreover, maintenance teams appreciate the ability to troubleshoot issues without removing or replacing the entire collector. For clients, this means lower operational costs and better return on investment.

SolarisKit HelioFlow solar collector can have every component accesses for repair, replacement, and recycling

Designed for End-of-Life Circularity

Disposal is another area where conventional solar thermal collectors fall short. The mixture of bonded materials makes it challenging to recycle these systems responsibly. HelioFlow, by contrast, is designed so that each material can be easily separated at end-of-life.

Polymers used in the construction are fully recyclable, and components are clearly marked for sorting. Even the packaging is designed to be reused or recycled, further enhancing the collector’s circular credentials.

This design foresight enables building projects to achieve LEED, BREEAM, and other sustainability certification points related to material reuse and waste reduction.

Aesthetics, Functionality, and Sustainability Combined

For architects and developers, a product must not only perform well but also complement the building design. The HelioFlow offers a modern and sleek appearance that enhances the look of villas, hotels, and commercial buildings with flat roofs.

Its compact design reduces visual clutter, and the prismatic geometry provides a futuristic look while optimising sunlight absorption. At the same time, it functions efficiently even in hard water conditions, which often damage traditional systems.

This ensures that sustainability does not come at the cost of appearance or performance.

SolarisKit HelioPro solar water heater installed at the Rixos Hotel in Ras Al Khaimah

A British Innovation Leading the Way

SolarisKit is proud to design and engineer the HelioFlow in the United Kingdom. Our commitment to innovation, quality, and sustainability drives everything we do. The HelioFlow solar collector is Solar Keymark certified and tested to EN12975/ISO9806 standards, ensuring compliance with global benchmarks.

As the push for decarbonisation accelerates, the demand for solar water heating systems that support circular economy goals will only grow. SolarisKit is already working with property developers, NGOs, and infrastructure planners around the world to integrate HelioFlow into new and retrofit projects.

Why MEP Engineers and Consultants Prefer HelioFlow

For professionals in mechanical, electrical, and plumbing design, HelioFlow offers a product that aligns perfectly with evolving regulations and client expectations. It supports low-carbon building targets, simplifies installation logistics, and provides superior lifetime value.

Thanks to its circular design, HelioFlow allows engineers to specify a solar water heater that meets both environmental and functional requirements. This makes it easier to meet net-zero certifications and demonstrate compliance with green building mandates.

Conclusion: Circularity is the Future of Solar Thermal Collectors

In an industry where sustainability, cost-efficiency, and durability are paramount, SolarisKit’s HelioFlow sets a new standard. By integrating circular design principles, a flat-packed structure, and low-carbon materials, it reimagines what solar water heaters can be.

For MEP engineers, architects, and green building consultants looking for a reliable, scalable, and sustainable solar thermal solution, HelioFlow offers a new an und unique solution to meet the needs of clients and the environment.

Discover how SolarisKit is reshaping solar thermal. Contact us today to learn more about integrating HelioFlow into your next building project.